MASONRY CAULKING PROJECTS

Brick Caulk (Or Brick Mortar Caulk) Repairs

Have you ever taken a close look at the brick caulk on the exterior of your home? If you’ve been noticing gaps, cracks, and even missing sections of brick caulk, there’s a good chance your home isn’t as weatherproof as you may have assumed. Brick caulk, also referred to as brick mortar caulk, acts as a seal that makes joints waterproof and weatherproof. Brick caulk seals joints and closes up any gaps between concrete and masonry.

Owing to the nature of its applications, brick caulk must be able to handle movement and not crack under stress. If you do not use a high-quality brick caulk, you’re bound to see stress cracks forming sooner rather than later. While brick and mortar are some of the oldest and most durable building materials available, even they need to be maintained to withstand time and Mother Nature.

If you have brick inside or outside of your home, it is especially important to test for loose mortar joints. Loose mortar joints can occur in anything made of brick; including walls, chimneys, and home exteriors. If harsh New York weather is allowed to come into contact with the deteriorating mortar joints, it could cause a lot of damage to your brick structure and create heavy costs for repair. Fixing your mortar joints will not only help your brick withstand harsh weather, but will improve the overall look. The materials required for fixing mortar joints are economical as well.

Repairing Mortar Joints

Protect your home by making minor mortar repairs. With colder temperatures here, now is the time to check your home for deteriorating mortar joints and loose mortar – and make any minor repairs before they turn into major headaches. Freezing rain, ice, snow and deicers, as well as freeze/thaw temperature cycles have the potential to cause costly damage. Left unrepaired, water can seep in between cracked, loose mortar and cause interior wall damage.

What Can Be Caulked?

Minor cosmetic repairs to mortar can be made on any type of brick walls – including garden walls, a home’s exterior brick and chimneys. And making such repairs is easier than many homeowners realize – all you need is a caulk gun and the right repair material.

A sanded acrylic mortar repair caulk – such as Quikrete Mortar Repair – will give the appearance of mortar in texture and color and is a more easily undertaken project for homeowners who are nervous about mixing mortar. The caulk’s sanded acrylic formula adheres to brick, block, stone and concrete surfaces, and the caulk tube’s square applicator tip is designed to smooth mortar joints during application of the caulk.

Try It Yourself

Before applying, make sure joints are clean, dry and free of grease, dust or loose particles, and remove all loose mortar from the joint. Apply the caulk by pushing the cartridge tip over the surface and forcing a bead of caulking into the opening. Do not apply any thicker than 3/8 inch in one application. Excess caulk can be wiped off with a damp cloth.

For homeowners looking to repair cracks in their fireplace, there is a specially designed mortar that is ideal for repairing damage commonly found in fireboxes. Quikrete Fireplace Mortar is a silicate-based refractory cement caulk ideal for tuck pointing damaged firebox mortar joints and repairing chips, cracks and breaks in fire brick commonly found in fireplaces and wood burning stoves. Once cured, the mortar provides superior adhesion for a durable repair while withstanding temperatures up to 2,000 F.

Using a caulk gun, the mortar is applied in strips no greater than 1/8-inch with multiple 1/8-inch layers for larger joints as needed. Once dry, start a low fire, keeping the temperature below 212 F until the mortar is dried thoroughly. It will typically take one to four hours to assure adequate drying and set time. Afterwards, increase the firebox temperature to 500 F for an additional one to four hours before routine usage.

As the weather changes, your house is more vulnerable to damage than ever. By taking these small steps that don’t require anything more than a caulking gun and about $5 per tube of caulk, homeowners can save significant money later by avoiding the need to make major repairs.

Cost Factor

Repairing mortar joints with a few inexpensive materials will save you from costly repair projects in the future. Since cold, foul weather can further deteriorate your mortar joints, fixing any problems with your mortar joints before the winter arrives is in your best interest. It shouldn’t take more than a few hours to repair your mortar joints.

Want to call a pro? Contact Lusitania Masonry and we will gladly help you out!

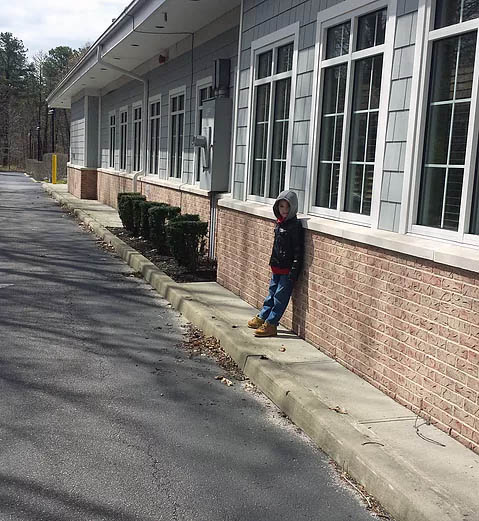

COMMERCIAL Masonry PROJECTS

SPECIALTY Masonry Services

Contact Lusitania Masonry

Masonry Office

448 Hagerman Avenue

East Patchogue, NY 11772

Masonry Inquiries

For any inquiries, questions or quotes, please call

631-520-8356 or fill out the form below.

Contact Lusitania

Tel: 631-520-8356.Tel: 877-520-5552.

Fax: 631-772-4768.

Email: ada@lusitaniamasonry.com.

Email: carlos@lusitaniamasonry.com.

Employment

To apply for a job with Lusitania Masonry, LLC., please send a cover letter together with your C.V. to: jobs@lusitaniamasonry.com.

Get A Masonry Quote

For a quote, inquiry or question about our services, please call 631-520-8356 or fill out the following form.